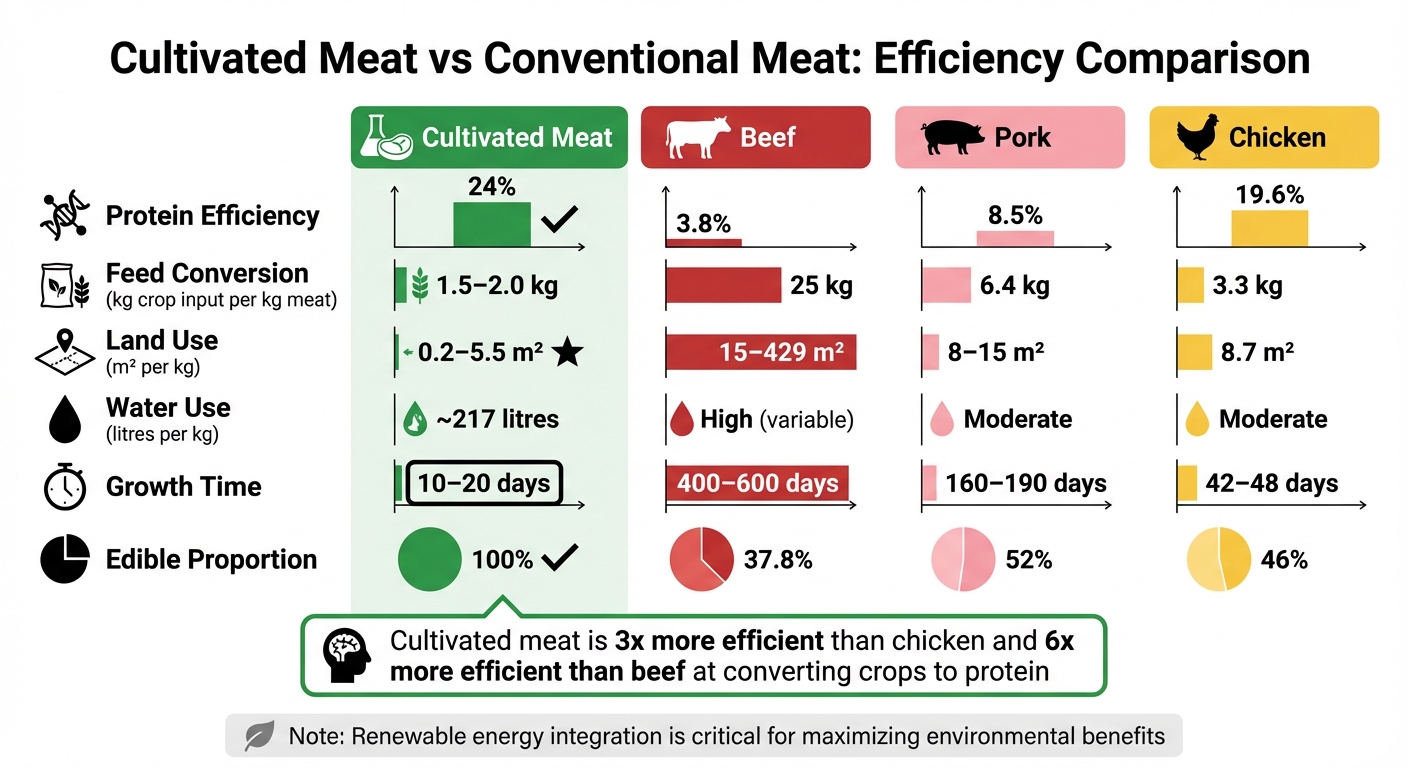

Which meat production method is more efficient? Cultivated meat outperforms conventional meat in protein efficiency, land use, and feed conversion. Unlike conventional farming, which requires raising entire animals, cultivated meat focuses solely on growing edible tissues, making it a more resource-efficient option.

Key Takeaways:

- Protein Efficiency: Cultivated meat converts 24% of feed protein into edible protein, compared to beef (3.8%), pork (8.5%), and chicken (19.6%).

- Feed Conversion: Cultivated meat needs only 1.5–2 kg of crop inputs per kg of meat, far less than beef (25 kg), pork (6.4 kg), and chicken (3.3 kg).

- Land Use: Cultivated meat requires 0.2–5.5 m² per kg, compared to beef's 15–429 m².

- Water Use: Cultivated meat uses about 217 litres/kg, generally lower than beef.

- Energy Use: Cultivated meat is energy-intensive, but renewable energy could reduce its carbon footprint significantly. This shift is central to the broader environmental benefits of cultivated meat.

Quick Comparison:

| Metric | Cultivated Meat | Beef | Pork | Chicken |

|---|---|---|---|---|

| Protein Efficiency | 24% | 3.8% | 8.5% | 19.6% |

| Feed (kg crop/kg) | 1.5–2.0 | 25 | 6.4 | 3.3 |

| Land Use (m²/kg) | 0.2–5.5 | 15–429 | 8–15 | 8.7 |

| Water Use (litres) | ~217 | High | Moderate | Moderate |

| Growth Time (days) | 10–20 | 400–600 | 160–190 | 42–48 |

The challenge? Cultivated meat’s energy demands are high, but renewable energy and scaling up production could make it a more viable alternative to conventional farming in the future.

Cultivated Meat vs Conventional Meat: Protein Efficiency and Resource Use Comparison

Is Lab Grown Meat the Solution for Sustainability?

sbb-itb-c323ed3

What is Protein Efficiency in Meat Production?

Protein efficiency measures how well a production system converts the protein in animal feed into edible protein in meat. In traditional livestock farming, this is calculated as the percentage of protein in feed that ends up in the final meat product[3]. For example, if a system is 25% efficient, it means 75% of the feed protein is lost to metabolic activities and the development of non-edible tissues.

A large portion of feed protein in conventional farming is consumed by processes like movement, regulating body temperature, and growing bones and organs - none of which contribute to the edible portion.

Cultivated Meat offers a different approach. By growing muscle and fat cells directly in bioreactors, it avoids the inefficiencies of maintaining an entire animal. Nutrients like glucose and amino acids are delivered directly to the cells through a culture medium[1], focusing solely on producing edible tissue. This process allows nearly all the output to be used as meat[1].

The difference in efficiency is stark. Traditional beef systems convert only about 3.8% of feed protein into edible meat protein, while pork and chicken achieve 8.5% and 19.6%, respectively. Cultivated Meat, however, is projected to reach approximately 24% protein conversion efficiency[1].

Feed-to-Protein Conversion Rates

Feed conversion efficiency highlights the disparity between growing an entire animal and producing only the parts we eat. In conventional systems, much of the feed energy goes towards non-meat functions like body temperature regulation, movement, and waste processing.

For Cultivated Meat, the Cultured Meat Conversion Ratio (CMCR) is estimated to be between 0.316 and 0.687[4], meaning it requires about 2 kg of glucose to produce 1 kg of meat[1]. On a dry matter basis, Cultivated Meat needs only 1.5 to 2.0 kg of crop inputs per kilogramme of fresh meat. Compare this to chicken at 3.3 kg, pork at 6.4 kg, and beef at a staggering 25 kg[5].

| Meat Type | Protein Conversion Efficiency | Feed Conversion Ratio (kg crop/kg meat) | Growth Time |

|---|---|---|---|

| Beef | 3.8% | 25 | 400–600 days |

| Pork | 8.5% | 6.4 | 160–190 days |

| Chicken | 19.6% | 3.3 | 42–48 days |

| Cultivated Meat | 24% | 1.5–2.0 | 10–20 days |

Beyond feed conversion, evaluating resource use - such as energy, land, and water - further underscores the differences between these systems.

Resource Requirements: Energy, Land, and Water

Efficient feed-to-protein conversion is just one piece of the puzzle. The overall resource footprint, including energy, land, and water use, also plays a critical role in assessing sustainability.

Traditional beef production, for instance, uses between 15 and 429 m² of land per kilogramme of meat annually[1]. Pork requires 8 to 15 m², and chicken about 8.7 m²[1]. Cultivated Meat, by contrast, drastically reduces land use to an estimated 0.2 to 5.5 m² per kilogramme[1][5], thanks to eliminating the need for grazing and significantly lowering the crop land required for feed.

Water consumption follows a similar trend. A modelled Cultivated Meat system uses around 217 litres of water per kilogramme of meat - 87 litres for production and 130 litres for reactor cleaning[1]. This is generally lower than the highly variable water requirements of conventional beef production.

Energy use, however, is more complex. Cultivated Meat production is energy-intensive due to the need for maintaining optimal bioreactor conditions, sterilisation, and mixing[5]. While traditional livestock systems emit methane and nitrous oxide from digestion and manure, Cultivated Meat's emissions are primarily carbon dioxide from industrial energy use[5]. The environmental benefits of Cultivated Meat hinge significantly on integrating renewable energy sources, which could greatly enhance its sustainability.

| Resource | Beef | Pork | Chicken | Cultivated Meat |

|---|---|---|---|---|

| Land Use (m²/kg/year) | 15–429 | 8–15 | 8.7 | 0.2–5.5 |

| Water Use (litres/kg) | High (variable) | Moderate | Moderate | ~217 |

| Primary Input | Forage/grain | Grain/soy | Grain/soy | Glucose/amino acids |

| Edible Proportion | 37.8% | 52% | 46% | 100% |

Environmental Impact Comparison

When looking beyond protein efficiency, the broader environmental footprint of meat production paints a striking picture. Comparing feed conversion efficiency with other environmental metrics highlights the stark differences in production methods.

One of the clearest distinctions between Cultivated Meat and traditional livestock farming carbon emissions lies in their source and intensity. Conventional livestock farming produces methane during digestion and releases nitrous oxide through manure, both of which are far more potent greenhouse gases than carbon dioxide, though they persist in the atmosphere for shorter periods. In comparison, Cultivated Meat's emissions come mostly from energy use, primarily in the form of carbon dioxide[5].

Traditional animal agriculture also contributes over a third of human-caused nitrogen emissions, largely through manure runoff. Cultivated Meat, however, operates within contained systems, significantly reducing the risk of open-air nitrogen discharges.

"CM has the potential to have a lower environmental impact than ambitious conventional meat benchmarks, for most environmental indicators, most clearly agricultural land use, air pollution, and nitrogen-related emissions." – The International Journal of Life Cycle Assessment[5]

The environmental benefits of Cultivated Meat are closely tied to the energy sources powering its production. Without renewable energy, Cultivated Meat might only outperform beef in terms of emissions, while remaining more carbon-intensive than pork or chicken[6]. This makes renewable energy integration a critical factor in achieving its full potential.

Greenhouse Gas Emissions by Protein Type

Meat production's carbon footprint varies significantly depending on the method and energy source. For example, conventional beef from a beef herd produces a median of 60.4 kg CO₂e per kilogramme of meat, while beef from a dairy herd averages 34.1 kg CO₂e[2][7]. On the other hand, near-term Cultivated Meat - using pharmaceutical-grade growth media - emits between 246 and 1,508 kg CO₂e per kilogramme of meat, making it 4 to 25 times more carbon-intensive than retail beef[7]. This high footprint is mainly due to the energy required to purify growth media for cell viability.

Looking ahead, the outlook improves significantly. Projections for 2030 suggest that with 100% renewable energy, Cultivated Meat could have a smaller carbon footprint than beef and pork, and be comparable to chicken[6][5]. Some estimates even suggest emissions as low as 19.2 kg CO₂e per kilogramme if the need for extensive growth media purification is eliminated[7].

"When using renewable energy during production... CM has a lower carbon footprint than ambitious production benchmarks beef and pork, and comparable to chicken." – CE Delft[6]

Transitioning from pharmaceutical-grade to food-grade growth media represents a major step forward, potentially reducing both costs and environmental impact[2][5].

| Protein Source | GHG Emissions (kg CO₂e/kg) | Primary Emission Type |

|---|---|---|

| Beef (Beef Herd) | 60.4–99.5 | CH₄, N₂O, CO₂ |

| Beef (Dairy Herd) | 33.4–34.1 | CH₄, N₂O, CO₂ |

| Pork | Lower than Cultivated Meat | N₂O, CO₂ |

| Chicken | Comparable to Cultivated Meat (renewables) | N₂O, CO₂ |

| Cultivated Meat (Near-term) | 246–1,508 | CO₂ (from energy) |

| Cultivated Meat (2030 Projection) | Lower than beef/pork (renewables) | CO₂ (from energy) |

Water and Land Use Footprints

Land use is where the differences between production systems are most pronounced. Conventional beef production requires vast amounts of land, while Cultivated Meat has a much smaller footprint. For instance, Cultivated Meat uses only 0.2 to 5.5 m² per kilogramme[1]. One model estimates that producing 1 kg of Cultivated Meat requires just 4.58 m² of land, achieving an impressive productivity of 40 g of protein per square metre[1].

Water use follows a similar trend, though with some nuances. Conventional animal agriculture is responsible for 41% of global green and blue water use[5]. Cultivated Meat, meanwhile, requires about 87 litres of water per kilogramme (excluding cleaning processes), which is generally less than beef's variable water demands[5][1]. Effective recycling of wastewater and spent media could further lower water usage[2].

Nitrogen efficiency is another factor to consider. Conventional systems lose a significant portion of fed nitrogen - around 84% for beef, 47% for swine, and 55% for broilers. Cultivated Meat, by comparison, loses about 76% without reuse[1]. However, since Cultivated Meat production occurs in contained systems, nitrogen waste can be captured and treated, avoiding the environmental runoff associated with conventional farming.

These reductions in land and water use address key drivers of biodiversity loss and habitat destruction. Additionally, the land saved through Cultivated Meat production could be repurposed for renewable energy projects or ecological restoration, creating opportunities for further sustainability gains.

Current Challenges and Future Potential

Cultivated Meat, while promising in theory, faces significant obstacles when it comes to scaling up production and addressing energy demands. The journey from laboratory success to commercial viability is riddled with challenges, including high costs, infrastructure needs, and energy consumption. Let’s dive into the specifics of these hurdles.

Production Scaling Requirements

One of the biggest challenges lies in transitioning from small-scale research to large-scale industrial production. At present, pharmaceutical cell cultivation typically uses bioreactor designs with capacities below 25,000 litres. To meet commercial demands, however, bioreactors would need to scale up to volumes of 200,000 litres - far beyond current pharmaceutical capabilities[2]. For perspective, producing just 10,000 tonnes of Cultivated Meat annually would necessitate around 130 production lines running simultaneously[8].

This shift isn’t just about size. It also requires moving from pharmaceutical-grade growth media to more affordable, food-grade alternatives, such as plant-based hydrolysates derived from soy or corn. These alternatives are crucial for reducing costs and minimising environmental impact. As Edward S. Spang from the University of California, Davis, points out:

"This study highlights the need to develop a sustainable animal cell growth medium that is optimised for high-density animal cell proliferation for ACBM to generate positive economic and environmental benefits."[2]

Maintaining industrial sterility is another major hurdle. Even a single contamination event could ruin an entire batch, making aseptic processes both essential and costly. Additionally, managing nitrogen waste presents a unique challenge. Unlike conventional farming, Cultivated Meat requires contained systems for nitrogen treatment. Gabrielle M. Myers from Iowa State University highlights this issue:

"Nitrogen management will be a key aspect of sustainability in CM production, as it is in conventional meat systems."[1]

Tackling these scaling issues is critical to preserving the protein efficiency that makes Cultivated Meat a potentially sustainable alternative to conventional meat. Without addressing these challenges, the environmental and economic benefits of this technology remain out of reach.

Renewable Energy Integration

Energy use is another critical factor in determining whether Cultivated Meat can deliver on its environmental promises. The production process is energy-intensive, requiring precise temperature control at 37°C for bioreactors and the synthesis of complex culture medium ingredients[8]. Without renewable energy, Cultivated Meat may only surpass beef in emissions, while remaining more carbon-intensive than pork or chicken[8].

However, when powered entirely by renewable energy, the environmental picture changes dramatically. Cultivated Meat’s carbon footprint becomes lower than beef and pork, and comparable to the most efficient chicken production methods[8]. As Pelle Sinke and colleagues note:

"CM is almost three times more efficient in turning crops into meat than chicken, the most efficient animal, and therefore agricultural land use is low."[8]

The potential for environmental benefits grows even further with hybrid renewable energy systems combining solar and wind power. These systems help stabilise electricity availability throughout the year, lowering costs and improving production reliability[9]. As global energy grids increasingly adopt renewables, the environmental profile of Cultivated Meat will improve automatically - unlike traditional livestock farming, which remains tied to methane and nitrous oxide emissions regardless of energy sources[8].

Ultimately, the integration of renewable energy is a linchpin for unlocking the environmental advantages of Cultivated Meat, ensuring that its efficiency translates into tangible benefits for the planet.

Conclusion

When it comes to protein efficiency, Cultivated Meat clearly outpaces conventional livestock farming. It’s about three times more efficient at converting crops into meat compared to chicken, which is already the most efficient traditional option. On top of that, it requires far less land to produce, directly contributing to a smaller environmental footprint[10][1].

This efficiency doesn’t just conserve resources - it also means fewer greenhouse gas emissions, contributing to lower overall emissions, especially when renewable energy is used in production. With renewables, Cultivated Meat’s carbon footprint is lower than beef and pork, and even on par with the most efficient chicken farming methods[10]. However, without renewable energy, the energy demands of production could cancel out these environmental benefits. As Pelle Sinke from CE Delft explains:

"While CM production and its upstream supply chain are energy-intensive, using renewable energy can ensure that it is a sustainable alternative to all conventional meats."[10]

The road ahead isn’t without obstacles. Scaling up production, shifting to food-grade growth media, and fully incorporating renewable energy are key challenges that must be addressed. Tackling these hurdles will solidify Cultivated Meat’s place as a sustainable and practical protein source.

For updates on Cultivated Meat advancements and its availability in the UK, check out Cultivated Meat Shop.

FAQs

Why is Cultivated Meat more protein-efficient than beef, pork, or chicken?

Cultivated meat stands out for its efficiency in protein production, delivering more protein per unit of resource compared to traditional meat. Research highlights its superior protein and energy productivity, using significantly less land and fewer resources. Additionally, it handles waste nitrogen more effectively, enhancing nitrogen use efficiency. These factors position cultivated meat as a promising solution to meet global protein demands while minimising its impact on the environment.

Why is cultivated meat so energy-intensive to produce?

Cultivated meat production consumes a lot of energy, primarily because of the intensive requirements of cell cultivation, running bioreactors, and maintaining tightly controlled environments. At present, these factors make it more energy-demanding than traditional meat production methods.

Will cultivated meat remain greener than conventional meat as production scales?

Studies indicate that cultivated meat has the potential to remain more environmentally friendly than conventional meat as production grows. Research shows it could cut greenhouse gas emissions by 78%–96% and reduce energy consumption by 7%–45%. With ongoing technological improvements, cultivated meat is becoming even more efficient in resource use. As the industry continues to develop, it is anticipated to sustain its smaller environmental footprint compared to traditional livestock farming.