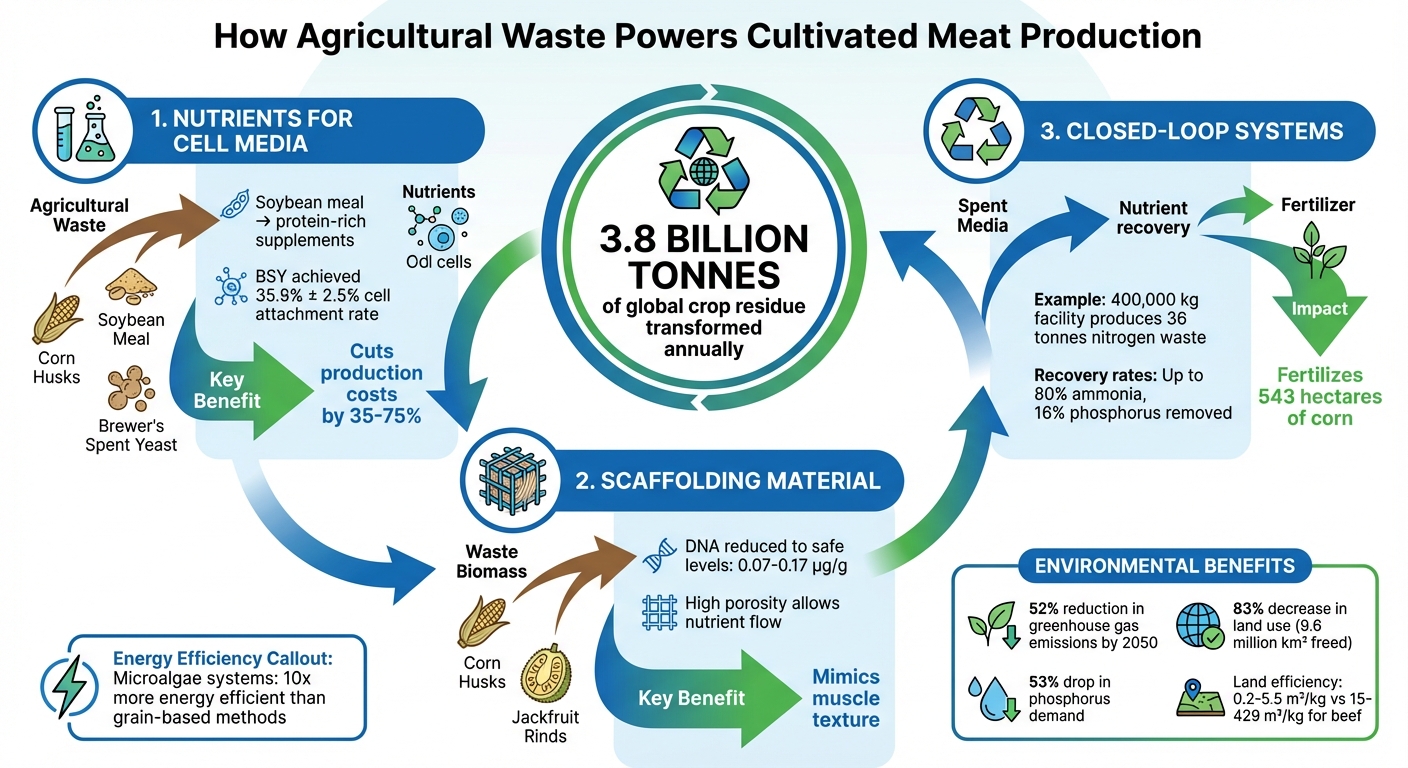

Agricultural waste - like corn husks, soybean meal, and brewer's spent yeast - is being repurposed to reduce the cost and impact of cultivated meat production. By using these by-products:

- Nutrients for Cell Media: Crop residues provide affordable carbon and nitrogen sources, cutting production costs by up to 75%. For example, soybean meal is processed into protein-rich supplements.

- Scaffolding Material: Fibrous waste like corn husks and jackfruit rinds serves as a framework for muscle cell growth, mimicking the texture of meat.

- Closed-Loop Systems: Spent media from meat production is processed to recover nutrients like nitrogen, which can be used as fertiliser.

This approach supports a circular system, turning 3.8 billion tonnes of global crop residue into valuable resources. Challenges like nutrient consistency and contamination risks remain, but innovations in processing and monitoring are paving the way for more efficient production.

How Agricultural Waste Powers Cultivated Meat Production: A Circular System

How Agricultural Waste Is Used in Cultivated Meat Production

Agricultural waste plays a key part in Cultivated Meat production by providing nutrients for cell media and acting as physical scaffolding. This approach not only lowers costs but also transforms materials that would otherwise go to waste into valuable resources. Here's a closer look at its dual role.

Agricultural Waste in Cell Media

Cell media require carbon (from glucose or starch) and nitrogen (from proteins and amino acids) to support cell growth. Traditional ingredients for these nutrients can be costly, but agricultural by-products offer a more affordable alternative. For instance, soybean meal is processed into soybean hydrolysate, a protein-rich supplement, while corn undergoes wet milling to extract starch, which is then converted into glucose [5].

Brewer's Spent Yeast (BSY) is another promising option. It provides carbohydrates, proteins, and micronutrients essential for cell growth [6]. In September 2025, researchers at University College London collaborated with Big Smoke Brewing Company in Esher to collect BSY, which they used to produce bacterial cellulose. This material achieved a 35.9% ± 2.5% attachment rate for L929 fibroblast cells within 24 hours [6].

"Incorporating brewing wastes into the CM supply chain would valorise this waste product, simultaneously reducing costs for brewers, and providing a sustainable feedstock for food production."

- Christian Harrison, Department of Aging, Rheumatology and Regenerative Medicine, UCL [6]

Using food residues as substrates can slash production costs by 35% to 75% compared to conventional protein sources [7]. However, nutrient consistency remains a challenge. For example, ammonium levels in brewing waste can vary widely, with some batches containing up to 25 times more than others, which impacts the predictability of cell growth [6].

Beyond nutrient supplementation, agricultural waste also helps create the structural framework needed for muscle cell growth.

Agricultural Waste as Scaffolding Material

Scaffolding provides the three-dimensional framework that muscle cells need to grow and develop a texture similar to conventional meat. Various agricultural by-products have shown promise in this role.

Corn husks, with their parallel striations, mimic the structure of skeletal muscle and help align cells correctly. Similarly, the fibrous "rags" of jackfruit rind offer a texture suitable for structured meat [1]. Decellularisation processes remove plant DNA, reducing it to safe levels of 0.07–0.17 µg/g, while preserving the supportive cellulose structure [1].

In May 2023, researchers at the National University of Singapore, led by Dejian Huang, extracted proteins such as zein, hordein, and secalin from spent cornmeal and brewery grains. These were used to create edible inks for 3D printing scaffolds. The printed scaffolds were then used to culture pork meat, successfully replicating the appearance and texture of traditional cuts [9].

"3D-printed plant protein scaffolds could bring new [opportunities] to develop cell-based meat with real meat appearance... they provide a cost-effective, edible material to replace expensive animal-derived proteins."

- Dejian Huang, Department of Food Science & Technology, National University of Singapore [9]

These scaffolds, with their high porosity, allow efficient nutrient flow and cell migration. By repurposing agricultural residues in this way, these innovations contribute to a circular economy in cultivated meat production, giving new value to what would otherwise be discarded.

sbb-itb-c323ed3

Environmental and Economic Benefits

Repurposing agricultural waste in Cultivated Meat production offers measurable advantages for both the environment and the economy.

Supporting a Circular Economy

Integrating agricultural by-products into the Cultivated Meat supply chain creates a closed-loop system, aligning with the United Nations' Sustainable Development Goal 12 on Responsible Consumption and Production. This approach allows producers to recover valuable nutrients and return them to the croplands that originally supplied the corn and soy feedstocks [5].

Switching to Cultivated Meat could lead to massive environmental gains by 2050. Projections suggest a 52% reduction in annual greenhouse gas emissions, an 83% decrease in land use (freeing up 9.6 million km²), and a 53% drop in global phosphorus demand [10].

Nitrogen recovery plays a central role in this sustainable model. For example, in Iowa, where animal manure currently supplies 30% of cropland nitrogen needs, a Cultivated Meat facility producing 400,000 kg annually generated 36 tonnes of nitrogen waste - enough to fertilise 543 hectares of corn [5]. Given nitrogen fertiliser costs ranging from £0.80 to £2.40 per kg, these recovered nutrients not only benefit the environment but also present a potential revenue opportunity [5].

"Nitrogen management will be a key aspect of sustainability in CM production, as it is in conventional meat systems."

- Gabrielle M. Myers, Researcher, Iowa State University [5]

These environmental efficiencies also translate into notable cost savings.

Cost Comparisons with Conventional Meat

Beyond sustainability, using agricultural waste significantly lowers production costs for Cultivated Meat. Cell culture media, the single largest expense in Cultivated Meat production, becomes more affordable when food residues are used as substrates [5].

Land use efficiency is another major advantage. While beef production requires between 15 and 429 m² per kg annually, Cultivated Meat production only needs 0.2 to 5.5 m² per kg [5]. This drastic reduction in space requirements directly reduces infrastructure and operational costs.

Microalgae systems further enhance efficiency. Yuki Hanyu, CEO of IntegriCulture Inc., explains, "From an energy efficiency point of view, the energy conversion along each step of the process is 10 times more effective when you use microalgae as opposed to grain" [4]. Between 2020 and 2024, IntegriCulture collaborated with Tokyo Women's Medical University to develop a circular cell culture system using microalgae to process spent media. This system successfully removed up to 80% of ammonia and 16% of phosphorus [4].

However, nutrient management costs remain a hurdle. Treating nitrogen in spent media currently costs about £1.96 per kg, while treating carbonaceous waste costs roughly £0.32 per kg. These expenses are higher than conventional livestock manure management due to the dilute nature of spent media and the need for additional processing infrastructure [5].

Challenges and Future Research

Overcoming technical and economic hurdles is critical to advancing the circular economy model discussed earlier. While the concept holds great potential, major obstacles still stand in the way of scaling it commercially. These challenges highlight the need for improved processing methods and robust quality assurance tools.

Variability and Contamination Risks

One of the biggest issues is inconsistency. Waste streams from different bioprocesses vary significantly in composition. For instance, in May 2024, researchers at University College Dublin and BiOrbic studied spent media from Chinese hamster ovary cells and Trametes versicolor fungus as potential feedstocks. They found the fungal waste to be highly acidic, with a pH of 5.5, and containing 56 mM of lactic acid, which inhibited secondary culture growth until the pH was adjusted [3].

Spent culture media often accumulate harmful substances like ammonia and lactate, which must be removed [2]. Similarly, agricultural waste can carry host cell proteins, residual metabolites, or antimicrobials that may hinder animal cell growth [3]. As production scales up and waste inputs become more diverse, maintaining sterile conditions becomes increasingly challenging [11].

"Maintaining reactors at the proper temperature, cleaning, mixing, filtration of waste products, and sterilization will likely require much higher direct energy inputs to the system than are required in conventional meat production."

- Gabrielle M. Myers et al., Frontiers in Nutrition [5]

Processing and Economic Requirements

Transforming variable waste streams into consistent, reliable feedstock requires advanced processing techniques. Approaches like ozonation, microwave thermal treatments, and high-pressure processing can break down cell walls, improve nutrient solubility, and minimise contamination risks [13]. Membrane filtration methods, such as ultrafiltration and nanofiltration, have achieved up to 90% protein recovery from waste streams like whey [13].

Artificial intelligence is also proving to be a valuable tool. For example, Deep Convolutional Neural Networks paired with Particle Swarm Optimisation achieved 100% accuracy in identifying spoiled materials, helping to prevent cross-contamination in the supply chain [12]. Real-time sensors that monitor pH, oxygen levels, and microbial metabolites can detect contamination early, reducing the risk of losing entire production batches [14].

Another pressing need is improving nutrient recovery from spent media. Research into wastewater treatments has shown promise, with some methods recovering up to 75% of nitrogen into concentrated streams, reducing the cost of land application [5]. Additionally, shifting from pharmaceutical-grade to food-grade media components - such as amino acids and glucose - offers a practical way to cut production costs while maintaining safety standards [8].

Meeting these processing and economic demands is crucial to unlocking the full potential of circular economy principles in cultivated meat production.

Conclusion

Agricultural waste offers a practical solution to two of cultivated meat's biggest hurdles: high production costs and its environmental footprint. By substituting pricey inputs like grain-based glucose and fetal bovine serum with crop residues and spent media, producers can slash expenses dramatically. For example, using spent media as fertiliser costs just £0.22–£0.25 per kilogramme of cultivated meat, compared to £0.67 for traditional wastewater treatment [5]. This cost advantage highlights the potential of a circular production model to reshape the industry.

The environmental advantages are equally striking. Cultivated meat production uses as little as 0.2 to 5.5 square metres of land per kilogramme, a fraction of the 15 to 429 square metres needed for conventional beef [5]. This efficiency is largely thanks to the circular approach, where nutrients from spent media are recycled back into agriculture, closing the gap between food production and farming. Research from IntegriCulture further supports this, showing that microalgae-based systems are up to 10 times more energy-efficient than grain-based methods [4].

The circular economy model tackles waste at every stage. With 3.8 billion metric tonnes of crop residue produced globally each year [1], what was once a disposal challenge can now serve as a valuable resource for scaffolding and cell growth in cultivated meat production.

For consumers, these advancements bring cultivated meat closer to achieving price parity with conventional meat while supporting regenerative farming practices. This technology proves that waste isn’t waste - it’s a resource ready to fuel a more efficient and sustainable production cycle.

FAQs

How does using agricultural waste make cultivated meat more affordable?

Agricultural waste can play a key role in cutting the costs of cultivated meat production by acting as an affordable and reusable resource. For instance, materials like spent growth media and cellular by-products can be transformed into fertilisers or other valuable inputs. This not only reduces resource expenses but also trims down waste management costs.

By integrating these practices, producers contribute to a circular economy, improving the efficiency of cultivated meat production while reducing its environmental impact. This method supports efforts to build a more sustainable and resource-conscious food system.

What challenges come with using agricultural waste in cultivated meat production?

Using agricultural waste in cultivated meat production comes with its fair share of challenges. A major obstacle lies in finding cost-efficient and effective ways to transform waste into the nutrient-rich materials necessary for cell growth. Right now, many processes rely heavily on expensive or animal-derived ingredients, which complicates the integration of waste into the production cycle.

Another significant challenge is scaling up production. Bioreactors need to handle large volumes of cells while maintaining their health and ensuring consistent quality in the final product. This task becomes even trickier when introducing materials derived from agricultural waste. On top of that, agricultural waste must meet strict safety, nutritional, and regulatory standards before it can be used, adding further complexity to the process.

That said, ongoing research and advancements in the field are opening up possibilities for more sustainable and circular methods in cultivated meat production. Agricultural waste could eventually play a key role in reshaping how we approach food systems in the future.

How does cultivated meat production benefit the environment through the circular economy?

The circular economy in cultivated meat production plays a key role in reducing waste and conserving resources. By reusing materials that would otherwise be discarded, it helps minimise environmental impact. For instance, agricultural by-products and waste, like spent media and cellular debris, can be turned into fertilisers, reducing waste and creating useful outputs.

Cultivated meat production is also far more efficient than traditional farming. It uses up to 95% less land, 78% less water, and produces up to 92% fewer greenhouse gas emissions compared to conventional beef farming. This method not only conserves essential resources but also contributes to lowering emissions, making it a step towards a more sustainable and environmentally friendly food system.